Precision-shaped components formed at room temperature using advanced cold forming techniques. Ideal for producing clevis pins, standard fasteners, hex nuts, and more. This process ensures excellent dimensional control, surface finish, and cost-effective mass production.

We manufacture cold forged parts in the range of M1.6 to M42 diameter, and up to 350 mm in length, including fasteners, studs, rivets, and complex non-standard components.

We forge critical parts at elevated temperatures to achieve maximum toughness and durability. With metal gathering, we create parts that require excess material in specific regions — perfect for industrial applications needing custom geometries and structural integrity.

Our hot forged parts range from M20 to M48 diameter, with lengths between 60 mm to 450 mm, including special bolts, flanged shafts, and parts requiring forged heads or uneven profiles.

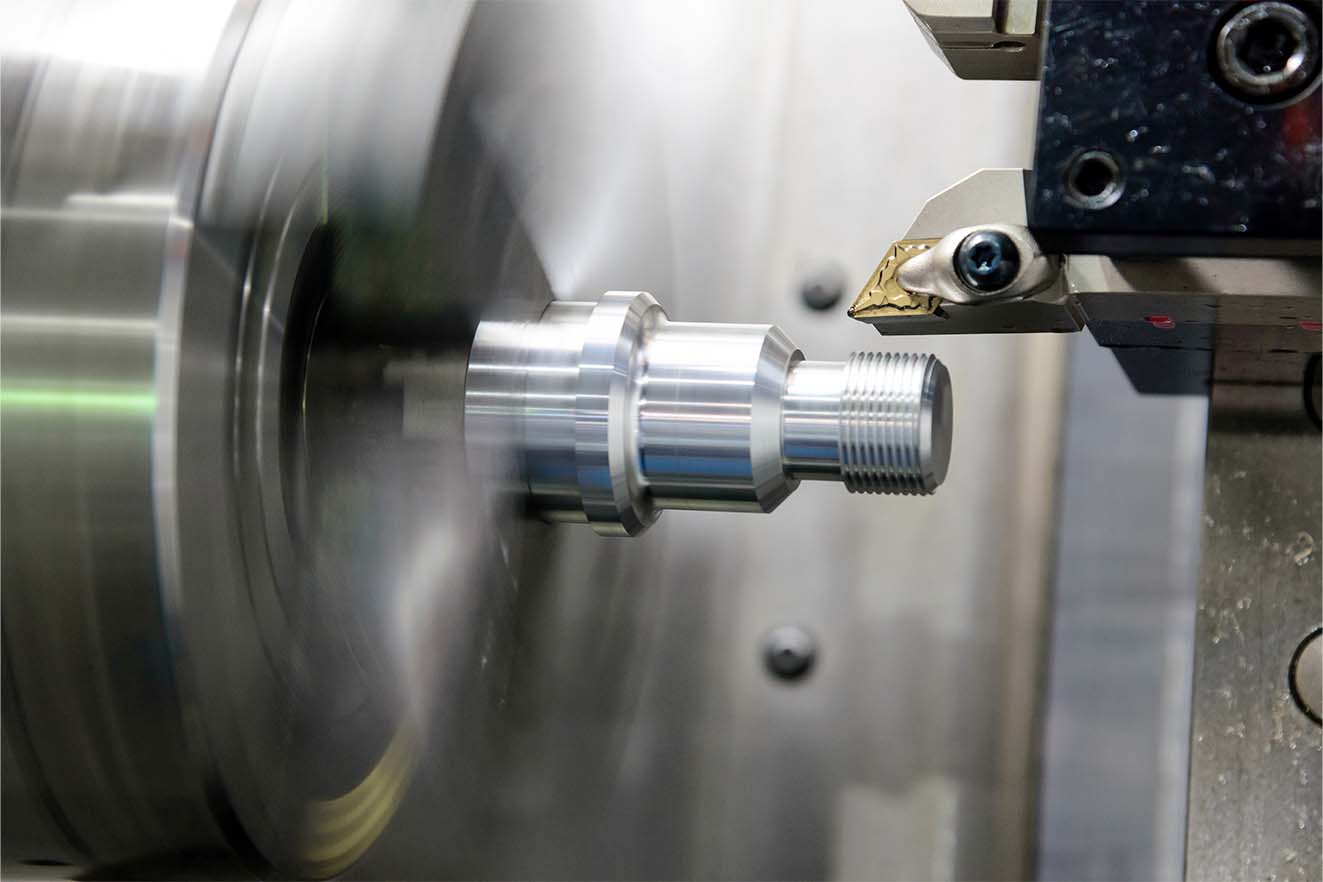

We utilize CNC turning, milling, grinding, slotting, and 4-axis contouring to deliver parts that meet the tightest tolerances. Whether it’s simple or complex, we ensure precision at every stage with CAD/CAM integration and in-process controls.

Our machining capabilities cover parts from 2 mm to 100 mm in diameter and up to 600 mm in length, suited for turned, milled, or ground components in various grades of carbon steel, alloy steel, and stainless steel.

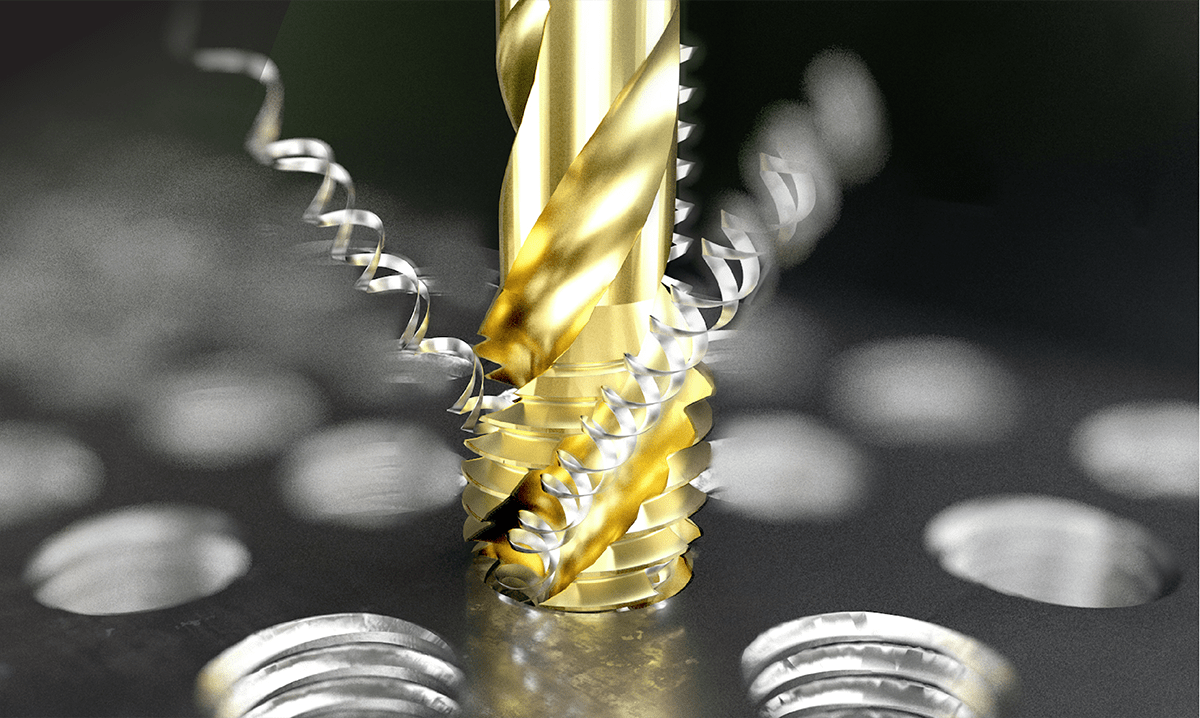

From blind holes to precision tapping, we perform drilling and tapping operations using multi-axis machines and rigid tapping setups. Clean threads, accurate depth, and perfect alignment — whether it’s alloy steel or hardened parts.

We handle holes from Ø1.5 mm to Ø25 mm, including deep hole drilling and fine thread tapping for steel, brass, and stainless components.

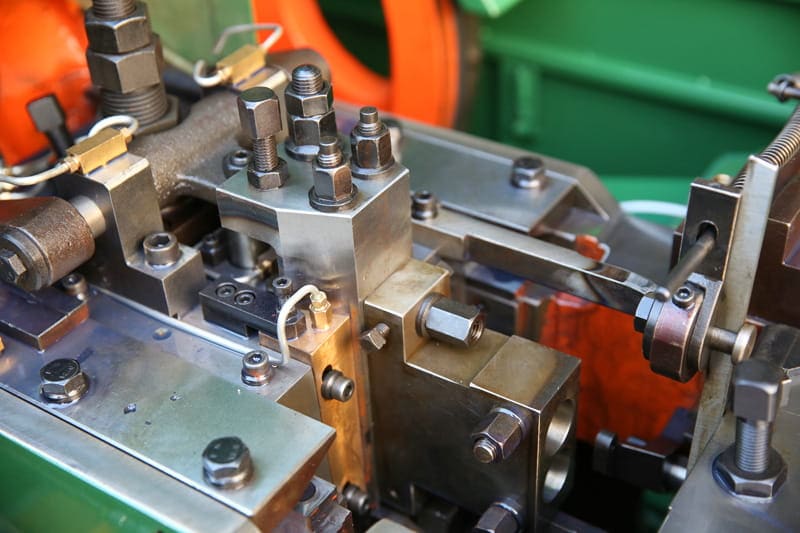

Our thread rolling setup produces cold-formed threads with enhanced fatigue strength and superior finish. Available using flat dies and circular dies, ideal for both standard and special thread profiles.

We roll threads up to M36 in metric and 1.5” in imperial, including external threads on studs, shafts, and special threaded pins.

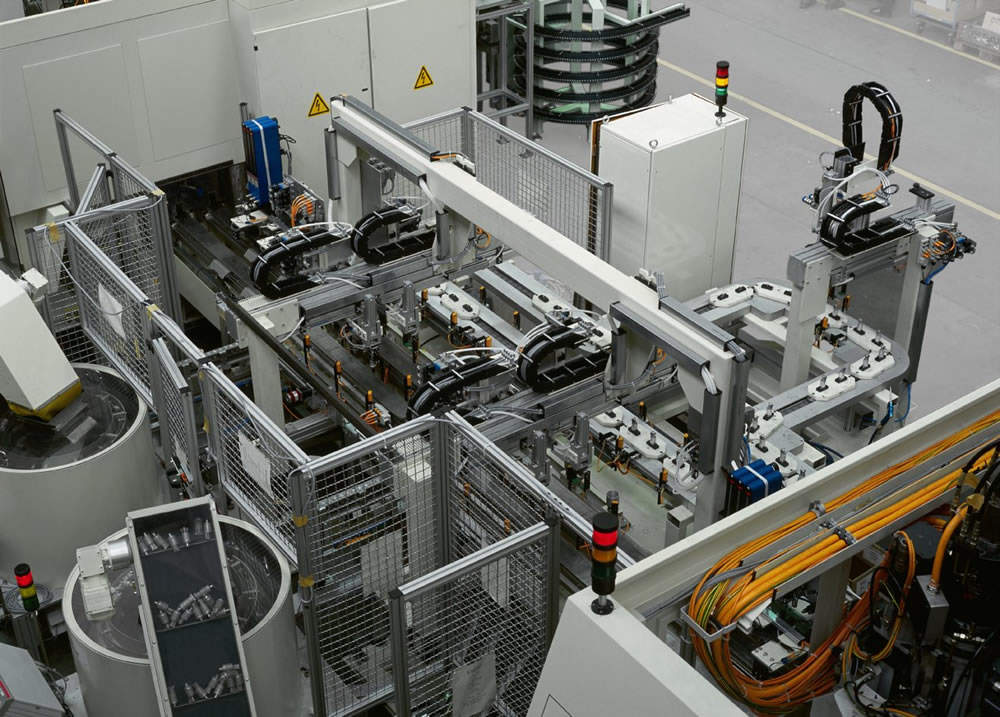

Cam-operated single spindle automats are used for mass production of pins, bushings, and precision shafts. Great for tight-tolerance work on small components where speed and cost matter.

Best suited for high-volume runs of components between Ø2 mm to Ø32 mm and lengths up to 100 mm.

We perform all key heat treatment processes — through hardening, case hardening, induction hardening, and vacuum treatment for stainless and alloy steels. Taiwan-made SCADA-monitored furnaces with auto black and dephos capability ensure uniform quality at temperatures above 1000°C.

Applicable for components up to 450 mm length and 50 mm diameter, achieving hardness levels up to HRC 60+, with traceability and in-house testing.