At Bhagwati Precision Industries, quality isn’t a checkbox — it’s a mindset woven into every stage of manufacturing. With IATF 16949 certification, precision-oriented teams, and stringent quality protocols, we deliver consistency from drawing to dispatch.

Every component undergoes a digitally tracked manufacturing journey using barcoded route cards, ensuring complete traceability from raw material to final shipment. With 100% digital quality records, our customers receive not just parts — they receive confidence, documentation, and control.

We maintain robust inspection systems to verify dimensional accuracy, material integrity, and surface finish at every stage. Our in-house lab is supported by ISO/IEC 17025-certified external partners for advanced metallurgical and mechanical tests.

Using high-precision tools such as calipers, micrometers, gauges, and Coordinate Measuring Machines (CMM), we validate all critical dimensions as per drawing.

Measures the material’s resistance to deformation, confirming heat treatment effectiveness and material properties.

.

Ensures the required Ra value is achieved to meet mating or sealing surface needs. Capable of testing up to Ra 0.1 µm.

Verifies surface coating thickness to ensure corrosion resistance and plating quality.

.

.

All parts undergo final visual inspection to ensure no defects like burrs, scratches, or surface non-conformities remain.

Confirms GO/NO-GO thread accuracy using calibrated thread plug and ring gauges.

.

Used to magnify and inspect complex profiles and radii which are difficult to check with contact-type gauges.

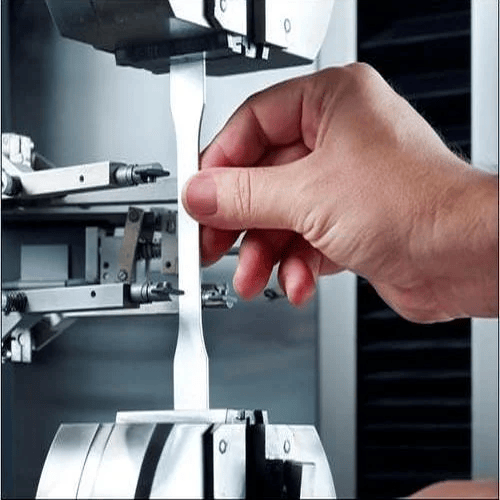

Evaluates the load-bearing capacity of materials and verifies tensile properties per ASTM or DIN standards.

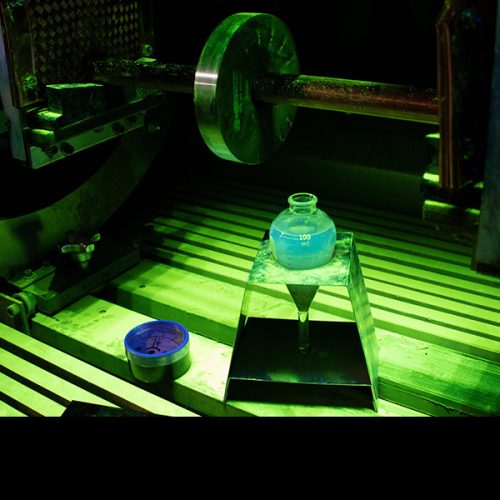

Measures the torque or coefficient of friction (CoF) between threaded elements, especially important for coated fasteners.

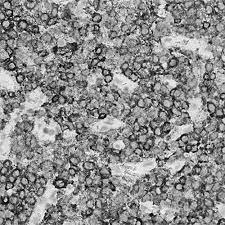

Cross-sectional grain structure analysis to check proper heat treatment, grain boundaries, and phase distribution.

Evaluates corrosion resistance of coatings and base material under ASTM B117 standards.

.

Detects surface and subsurface cracks in ferromagnetic materials.

Detects surface cracks, hardness variations, and mixing errors in high-volume fasteners.

Ensures 100% inspection of components for dimensional accuracy, surface finish, and contamination.

Contactless dimensional checking solution for high-precision bores and inside diameters.

.

Confirms elemental composition using spectrometry to ensure material grade compliance.

Examines grain size, phase distribution, and internal structure to evaluate heat treatment or alloying results.

Involves tensile, yield, elongation, and impact testing to determine mechanical behavior of material.

Each shipment is accompanied by a full suite of quality and compliance documents.

Our QMS is not just on paper — it's on the shop floor, in our culture, and in our controls.